Why a surface integral is used to represent flow of B into and out of the control volume? Explanation: Fluid can enter into or exit from the control volume through the control surface. If this flow velocity is integrated along the control surfaces, we can get the net inflow or outflow of fluid to the control volume.

Q. What is the purpose of the Reynolds Transport Theorem?

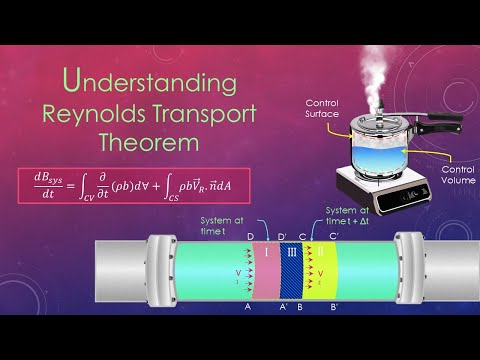

Reynolds transport theorem (RTT) expresses the relationship between the rate of change of extensive property of a system and for the control volume. The main purpose of the RTT is to provide the link between the system and control volume.

Table of Contents

- Q. What is the purpose of the Reynolds Transport Theorem?

- Q. What is the relationship between the Reynolds transport theorem and the material derivative?

- Q. Which of these terms need a volume integral While Modelling steady flow?

- Q. How many equations are related to solving a flow field?

- Q. Why is hydrodynamics important?

- Q. What is the difference between aerodynamics and hydrodynamics?

- Q. What is hydrodynamic system?

- Q. What is the difference between hydrodynamic and hydrostatic bearing?

- Q. What is hydrodynamic effect?

- Q. What oil goes in a hydrostatic transmission?

- Q. Why is the hydrostatic balance important?

- Q. How does a hydrostatic drive system work?

- Q. What is the difference between automatic and hydrostatic transmission?

- Q. How often should you change hydrostatic transmission fluid?

- Q. Why does my hydrostatic transmission won’t move?

- Q. How do you troubleshoot a hydrostatic transmission?

- Q. How do you purge air from a hydrostatic transmission?

- Q. Can you adjust a hydrostatic transmission?

- Q. How do you fill a hydrostatic transmission?

- Q. How can I make my hydrostatic transmission faster?

- Q. Why do hydrostatic transmissions whine?

- Q. How much does it cost to replace a hydrostatic transmission?

- Q. How does Husqvarna hydrostatic transmission work?

- Q. How do you adjust a John Deere hydrostatic transmission?

- Q. How do you adjust the belt tension on a riding lawn mower?

Q. What is the relationship between the Reynolds transport theorem and the material derivative?

The Reynolds transport theorem can be thought of as the integral form of the material derivative. It mainly relates the rate of change of an extensive property of a given material volume to the rate of change of the corresponding intensive property.

Q. Which of these terms need a volume integral While Modelling steady flow?

Which of these terms need a volume integral while modelling steady flows? Explanation: The convection and diffusion terms need surface integrals and not volume integrals. The source and rate of change terms need volume integral. Since the flow taken is a steady flow, the rate of change term will be equal to zero.

Q. How many equations are related to solving a flow field?

5 equations

Q. Why is hydrodynamics important?

2.016 Hydrodynamics Understanding marine hydrodynamics can help us to design better ocean vessels and to understand physical ocean processes. Studying marine hydrodynamics provides a greater understanding of a wide range of phenomena of considerable complexity involving fluids.

Q. What is the difference between aerodynamics and hydrodynamics?

Aerodynamics deals with the motion of air. Hydrodynamics deals with the motion of water. They both come under Fluid Dynamics. The difference is that aerodynamics does not care about the gravity effects most of the time but hydrodynamics usually accounts for gravity effects.

Q. What is hydrodynamic system?

Hydrodynamics is the study of fluids in motion. It is about when we use that motion to do useful work – for example, a fluid flywheel. When fluid flows, that flow may be smooth and steady (laminar flow) or unsettled and disturbed (turbulent flow).

Q. What is the difference between hydrodynamic and hydrostatic bearing?

For hydrostatic bearings, the gap between the supported and supporting members is filled with a lubricant supplied by an external pump. In contrast, hydrodynamic bearings generate pressure in the lubricant film through the relative motion between supporting and supported members.

Q. What is hydrodynamic effect?

This phenomenon is known as the hydrodynamic effect, and is the method by which the lip material avoids immediate hardening due to excessive frictional heat. In essence, the lip is riding on a layer of fluid and not the shaft.

Q. What oil goes in a hydrostatic transmission?

The fluid recommended for Hydro-Gear transmissions and pumps is a 20W-50 motor oil or 15W-50 synthetic motor oil.

Q. Why is the hydrostatic balance important?

A hydrostatic balance is a particular balance for weighing substances in water. Hydrostatic balance allows the discovery of their specific gravities. This equilibrium is strictly applicable when an ideal fluid is in steady horizontal laminar flow, and when any fluid is at rest or in vertical motion at constant speed.

Q. How does a hydrostatic drive system work?

Hydrostatic Operation Usually powered by a standard engine, the hydrostatic pump uses pressurized oil to move pistons in the hydrostatic drive system. The movement of the pistons transfers power to the hydrostatic motors, which then engage the drive wheels on your lawn mower.

Q. What is the difference between automatic and hydrostatic transmission?

An automatic transmission performs much like the transmission in a car — you control speed with the gas pedal. A hydrostatic transmission works like an automatic transmission, but uses fluid rather than belts to transfer power from the engine to the wheels.

Q. How often should you change hydrostatic transmission fluid?

If the dipstick or sight glass reveals the reservoir needs to be topped off, add the fluid recommended by the manufacturer for your model. As a rule of thumb, a complete replacement of the hydro fluid in any tractor or mower model without a sealed system should occur after 1,200 service hours.

Q. Why does my hydrostatic transmission won’t move?

Entraining. By far, the most common reason for hydrostatic transmission failure is old hydraulic fluid. John Deere states that “Operating outside of the recommended oil air temperature range may cause premature hydrostatic transmission failure.” Oil must be changed when its anti-foam additive decays.

Q. How do you troubleshoot a hydrostatic transmission?

Troubleshooting Hydrostatic Drives If the system is overheating, check the oil level in the tank, inspect the heat exchanger, check the inline pressure filters, inspect the crossport relief valves, and check the pump and motor case drains for excessive bypassing.

Q. How do you purge air from a hydrostatic transmission?

Push motion control levers forward all the way and hold for five seconds. Pull motion control levers to full reverse position and hold for five seconds. Repeat steps 6 and 7 three times. This purges any air from the hydraulic transmission system.

Q. Can you adjust a hydrostatic transmission?

Hydrostatic transmissions feature control rod linkage from the speed control lever (or foot pedal on some models) to the hydrostatic transmission. These control rods are adjustable. By rotating the threaded linkage connector ferrules, the length and the resulting range of movement at the regulator valve can be altered.

Q. How do you fill a hydrostatic transmission?

Fill the hydrostatic transmission oil filter reservoirs with new hydrostatic transmission oil. Pour the transmission oil into the reservoirs by hand. Fill the oil reservoir to the full line that is embossed on the side of the reservoir tank.

Q. How can I make my hydrostatic transmission faster?

How to make a hydrostatic lawn mower faster: proposed hydrostatic transmission modifications

- Install larger tires. The first thing you should try is bigger tires.

- Work on or replace the blades.

- Take off the governor.

- Put a bigger pulley on it.

- Purge the hydraulic drive.

Q. Why do hydrostatic transmissions whine?

Some noise is normal; your engine is basically driving a hydraulic pump, from a belt which goes from it’s crankshaft pulley, which in turn, drives the hydro-static drive axle. With air in the drive, it can be more noisy than it should, older fluid can be a cause also.

Q. How much does it cost to replace a hydrostatic transmission?

If you have a hydrostatic transmission built in the past 15 years you can expect to pay somewhere in the area of $200 for a new transmission. The problem is unlike engine designs that are very similar throughout the years you may find that your model transmission is no longer supported.

Q. How does Husqvarna hydrostatic transmission work?

Hydrostatic transmissions use oil, under pressure, to provide movement for the tractor. The fluid is pressurized with a pump inside the transmission. If any air is in the fluid, the pump will try to pressurize air. Also, if you experience loss of drive, or slower response, then the transmission should be purged first.

Q. How do you adjust a John Deere hydrostatic transmission?

Adjusting Neutral Start Switch

- Open right-hand access cover.

- Position drive control pedal in NEUTRAL and engage Park brake.

- Safely lift and block machine.

- Start engine run at slow idle.

- Move hydrostatic control pedal to the forward and reverse position.

- If engine does not stop, switch adjustment is required.

Q. How do you adjust the belt tension on a riding lawn mower?

The Process To Adjust Belt Tension On Riding Lawn Mower

- Step #1: Activate Parking Mode.

- Step #2: Disconnect Battery Cable.

- Step #3: Pull Lawn Mower Deck Upwards.

- Step #4: Locate The Bracket.

- Step #5: Loosen The Bracket Screws.

- Step #6: Don’t Remove The Screws.

- Step #7: Adjust The Belt.

- Step #8: Tighten The Screws.