Fresnel absorption depends on the reflectivity of the material while the latter depends on the atomic density. The Keyhole model of welding is what leads to the narrow heat affected zone. The high intensity radiation produced by the welding processvapourizes the metal and penetrates deep into the metal.

Q. What is heat affected zone What is its importance in producing a crack free weld?

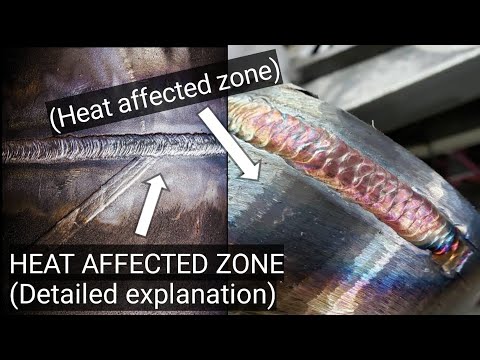

The heat affected zone (HAZ) is the area adjacent to the weld that was heated high enough to affect its microstructure but not enough to melt it. By undergoing microstructural changes the HAZ has different mechanical and physical properties than the weld and the adjacent base metal.

Table of Contents

- Q. What is heat affected zone What is its importance in producing a crack free weld?

- Q. Which of the following are effects of the HAZ?

- Q. How do you calculate heat affected zone in welding?

- Q. What do you mean by heat affected zone?

- Q. Is brazing as strong as the base material?

- Q. What is stronger welding or brazing?

- Q. What is the best torch for brazing?

- Q. What gases are used for brazing?

- Q. Is acetylene hotter than Mapp?

- Q. Why was MAPP Gas discontinued?

- Q. What replaced Mapp gas?

- Q. How hot is MAPP gas torch get?

- Q. Is a torch hotter than a lighter?

- Q. Can I use propane torch with MAPP gas?

- Q. What part of a torch flame is hottest?

- Q. What is the hottest flame color?

- Q. How hot is the flame from a Bernzomatic propane torch?

- Q. How hot do you have to get steel to bend it?

- Q. What’s hotter than a propane torch?

- Q. Does heating Steel weaken it to bend?

- Q. Can you heat steel to bend it?

- Q. Does heat weaken metal?

Q. Which of the following are effects of the HAZ?

Effects of the HAZ. The heat affected zone leads to structural changes in the metal that weaken the part in this area. A metal’s mechanical properties such as fatigue resistance, distortion, and surface cracking are affected.

Q. How do you calculate heat affected zone in welding?

9. Heat-affected zone area calculated from the locus of the peak temperatures as a function of plate gap for different peak temperatures (plate dimensions, 0.3 m long, 0.3 m wide and 0.04 m thick; welding voltage, 45 V; electrode immersion, 0.95 X lo2 m).

Q. What do you mean by heat affected zone?

The heat affected zone (HAZ) is a non-melted area of metal that has undergone changes in material properties as a result of being exposed to high temperatures. These changes in material property are usually as a result of welding or high-heat cutting.

Q. Is brazing as strong as the base material?

A properly made brazed joint (like a welded joint) will in many cases be as strong or stronger than the metals being joined. If you don’t have to melt the base metals to join them, it doesn’t matter if they have widely different melting points. You can braze steel to copper as easily as steel to steel.

Q. What is stronger welding or brazing?

Welded joints are usually as strong or stronger than the base materials. Brazing differs from welding in that the temperature is considerably lower and does not melt the base metals. Rather, the heat source melts a filler metal and draws it into the joint by capillary action.

Q. What is the best torch for brazing?

Best Portable Oxygen Acetylene Brazing Torch – Ameriflame TI350T. This is the most portable kit on this list as it has a small, lightweight tank to facilitate movement for small, light jobs. Specifically, it has a tank capacity of 10 cf of acetylene with 20 cf of oxygen.

Q. What gases are used for brazing?

While acetylene gas is always required as the fuel for gas welding, braze welding can be performed with the other fuel gases such as propane, natural gas, propylene, etc., as well as with acetylene.

Q. Is acetylene hotter than Mapp?

Although acetylene has a higher flame temperature (3160 °C, 5720 °F), MAPP has the advantage that it requires neither dilution nor special container fillers during transport, allowing a greater volume of fuel gas to be transported at the same given weight, and it is much safer in use.

Q. Why was MAPP Gas discontinued?

The original MAPP gas production came to an end in 2008 as the sole plant making it discontinued the production. It is found that the oxygen flame of MAPP gas cylinders is not entirely appropriate for welding steel, due to the high concentration of hydrogen in the flame.3 dagen geleden

Q. What replaced Mapp gas?

Mapp-Pro

Q. How hot is MAPP gas torch get?

3,730 degrees Fahrenheit

Q. Is a torch hotter than a lighter?

If you’ve always lit your cigars with a regular lighter, you may not know the difference. However, torch lighters do produce a hotter flame, which means you don’t have to puff on the cigar to get it lit to your satisfaction.

Q. Can I use propane torch with MAPP gas?

Yes, MAPP gas works well on a propane torch nozzle, but the flame will be hotter than a propane flame. MAPP is better for soldering copper pipe, but too hot for many smaller copper items.

Q. What part of a torch flame is hottest?

The outer flame is a dark transparent blue. The inner flame is lighter, opaque in color, and comes to a sharp tip inside the outer flame. Just in front of that lighter flame is the “sweet spot,” or the hottest part of the flame.

Q. What is the hottest flame color?

blue

Q. How hot is the flame from a Bernzomatic propane torch?

3,600 degrees Fahrenheit

Q. How hot do you have to get steel to bend it?

between 200 and 300 degrees F

Q. What’s hotter than a propane torch?

Propylene burns substantially hotter than propane all on its own, but this inherent heat advantage is also enhanced by a unique internal feature of this torch.

Q. Does heating Steel weaken it to bend?

It’s often used to create steel that is stronger than annealing the metal, but also creates a less ductile product. So, heat can indeed make metal weaker.

Q. Can you heat steel to bend it?

Metal Bending You can make simple bends in iron and steel using nothing more than a torch to heat and soften the metal. With a soapstone pencil, mark a line across the stock to indicate the center of the bend. Light the torch and adjust it to a neutral flame.

Q. Does heat weaken metal?

Referred to as allotropic phase transformation, heat typically makes metals softer, weaker, and more ductile. Ductility is the ability to stretch metal into a wire or something similar. Heat also can impact the electrical resistance of metal. Metals heated to certain temperatures also can lose their magnetism.