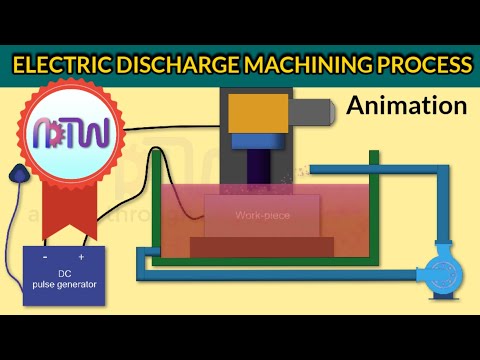

In EDM, a potential difference is applied between the tool and workpiece. Both the tool and the work material are to be conductors of electricity. The tool and the work material are immersed in a dielectric medium. Generally kerosene or deionised water is used as the dielectric medium.

Q. Which material Cannot be machined by EDM?

2. Which of the following material cannot be machined using electronic discharge machine? Explanation: Wood is a bad conductor of electricity and hence cannot be machined using electronic discharge machine.

Table of Contents

- Q. Which material Cannot be machined by EDM?

- Q. Why DC is used in EDM?

- Q. What is the application of EDM?

- Q. What is the function of dielectric fluid?

- Q. Why flushing is essential in electro discharge machining?

- Q. What are the main dielectric fluid flushing method used in EDM?

- Q. What are the methods of dielectric flushing?

- Q. Which type of holes can be produced through drilling using electro discharge machining?

- Q. Which statement is true for EDM?

- Q. What is die sinking?

- Q. What are the values of gaps between the electrodes in EDM?

Q. Why DC is used in EDM?

Pulsed dc power supply is the critical component in the micro EDM for achieving the required parameters of accuracy, finish & size of micro holes. Better workpiece material removal and low tool electrode wear can achieve by using appropriate power supply.

Q. What is the application of EDM?

Electrical discharge machining (EDM), also known as spark machining, spark eroding, die sinking, wire burning or wire erosion, is a metal fabrication process whereby a desired shape is obtained by using electrical discharges (sparks).

Q. What is the function of dielectric fluid?

Dielectric liquids are used as electrical insulators in high voltage applications, e.g. transformers, capacitors, high voltage cables, and switchgear (namely high voltage switchgear). Its function is to provide electrical insulation, suppress corona and arcing, and to serve as a coolant.

Q. Why flushing is essential in electro discharge machining?

A. Flushing is important because eroded particles must be removed from the gap for efficient cutting. Flushing also brings fresh dielectric oil into the gap and cools the electrode and the workpiece. The deeper the cavity, the greater the difficulty for proper flushing. Improper flushing causes erratic cutting.

Q. What are the main dielectric fluid flushing method used in EDM?

Pressure flow types is a widely used method used for flushing dielectric fluid in EDM. The fluid is forced through holes in the electrode to pass through the gap between the tool and the work. The fluid under pressure flushes out the solid particles and cools the work and tool electrode.

Q. What are the methods of dielectric flushing?

Various methods for dielectric flushing: (a) suction through electrode (b) suction through workpiece, (c) pressure through velectrode, (d) pressure through workpiece, (e) jet flushing, (f) periodic cycling of electrode [Courtesy: HMT, Bangalore, India]

Q. Which type of holes can be produced through drilling using electro discharge machining?

7. Which type of holes can be produced through drilling using Electro discharge machining? Explanation: Drilling of work piece using EDM produced holes which can be irregular, curved, tapered as well as inclined holes. 8.

Q. Which statement is true for EDM?

Correct answer is option ‘A’.

Q. What is die sinking?

Alternative Title: die sinking. Diesinking, process of machining a cavity in a steel block to be used for molding plastics, or for hot and cold forging, die-casting, and coining.

Q. What are the values of gaps between the electrodes in EDM?

What are the values of gaps between the electrodes in EDM? Explanation: In EDM, very small gaps that range between 0.01 – 0.5 mm are maintained.