Aluminum

Aluminum is one of the most popular metals used in die casting. Aluminum is a very lightweight metal, so it’s great for creating lightweight parts without sacrificing strength. Aluminum parts can also withstand higher operating temperatures and have more finishing options.

Q. How do you cast metal parts?

The basic metal casting process

Table of Contents

- Q. How do you cast metal parts?

- Q. Which type of metal is used in the casting process?

- Q. What is metal Mould casting?

- Q. What metals are best for casting?

- Q. What are the common materials used for permanent Mould casting?

- Q. What is the purpose of metal casting?

- Q. What kind of metal can be cast in an ingot mold?

- Q. What can you do with metal casting supplies?

- Q. What kind of mold is best for casting gold?

- Q. How do you cast metal from molten metal?

- Step 1: Create the pattern. Before you make your mold, you must create a pattern to determine the mold’s shape.

- Step 2: Make the mold.

- Step 3: Choose the metallic alloy.

- Step 4: Melt the alloy.

- Step 5: Pour into the mold.

- Step 6: Remove the casting from the mold.

- Step 7: Finishing.

Q. Which type of metal is used in the casting process?

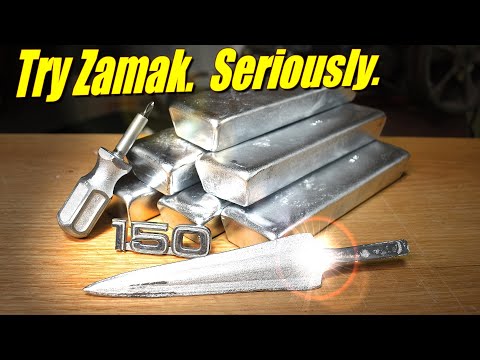

Common casting metals are aluminum, magnesium, and copper alloys. Other materials include tin, zinc, and lead alloys and iron and steel are also cast in graphite molds.

Q. What is metal Mould casting?

Metal casting is defined as the process in which molten metal is poured into a mould that contains a hollow cavity of a desired geometrical shape and allowed to cool down to form a solidified part. The term ‘casting’ is also used to describe the part made by the casting process which dates back 6000 years.

Q. What metals are best for casting?

8 Key Metals Used in Casting

- Gray Iron.

- White Iron.

- Ductile Iron.

- Stainless Steel.

- Carbon Steel.

- Copper-Based Alloy.

- Nickel-Based Alloy. Nickel-based alloys have excellent corrosion resistance.

- Aluminum. Aluminum alloy, a popular choice in die casting, is a very castable alloy.

Q. What are the common materials used for permanent Mould casting?

Common casting metals are aluminium, magnesium, and copper alloys. Other materials include tin, zinc, and lead alloys and iron and steel are also cast in graphite molds. Typical products are components such as gears, splines, wheels, gear housings, pipe fittings, fuel injection housings, and automotive engine pistons.

Q. What is the purpose of metal casting?

Metal casting is the process of making objects by pouring molten metal into an empty shaped space. The metal then cools and hardens into the form given to it by this shaped mold. Casting is often a less expensive way to manufacture a piece compared with machining the part out of a piece of solid metal.

Q. What kind of metal can be cast in an ingot mold?

We offer ingot molds in graphite, cast iron, and steel. They are ideal for casting precious metals such as gold and silver, especially if you’re aiming for fine detailed cast results. Our 3D molds offer detailed shapes for casting designs in both precious and non-precious metals.

Q. What can you do with metal casting supplies?

The casting process has been used for thousands of years for making sculpture, jewelry, tools and more. Here at PMC Supplies, we specialize in offering tools for both melting down precious and non-precious metals and pouring them into a mold.

Q. What kind of mold is best for casting gold?

Conical slag molds are ideal for separating impurities from gold ore concentrates. The conical molds unique shapes helps the pure gold settle at the bottom of the cast. Ideal for casting metals into flat and wire stock for making jewelry.

Q. How do you cast metal from molten metal?

Pour the molten metal into the mold cavity. If it is a small casting, you may simply pour from the crucible where the metal was heated directly into the mold. A larger casting may require a small team to support heating the metal inside of a furnace, and transferring the metal into a larger crucible or ladle before being poured into the mold.