Allocasuarina luehmannii

Q. What wood is used for Maori carvings?

greenstone

Table of Contents

- Q. What wood is used for Maori carvings?

- Q. What did the Maori carve?

- Q. What wood is best for carving NZ?

- Q. What is the most expensive wood in NZ?

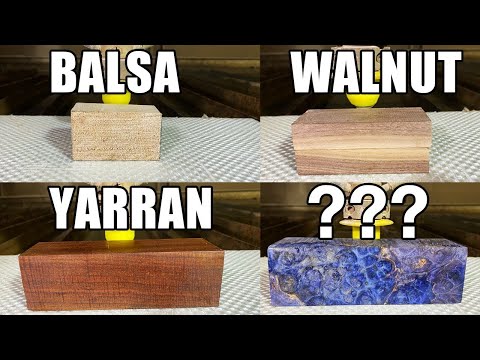

- Q. What is the toughest wood in the world?

- Q. What is the heaviest and hardest wood in the world?

- Q. Does epoxy keep wood from warping?

- Q. How do you protect wood from warping?

- Q. How do I keep my 6×6 post from warping?

- Q. How do you keep pressure treated wood from cracking?

- Q. What is the fastest way to dry pressure treated wood?

- Q. Do you need to let pressure treated wood dry?

- Q. What happens if you paint pressure treated wood too soon?

- Q. Is it better to stain or paint pressure treated wood?

- Q. Why does pressure treated wood feel wet?

- Q. Is it OK to build with wet pressure treated wood?

- Q. Can treated lumber get wet?

- Q. How long does it take for pressure treated wood to rot?

- Q. Will wooden posts rot in concrete?

- Q. Will pressure treated wood rot if buried?

- Q. Which lasts longer redwood or pressure treated?

- Q. Can you get pressure treated redwood?

- Q. Is Redwood ever pressure treated?

- Q. What are the disadvantages of Redwood?

Q. What did the Maori carve?

Māori carving developed its own unique style, including the curved patterns and spirals inspired by New Zealand plants such as ferns. Elaborately carved pātaka (food storehouses) and waka taua (war canoes) showed a tribe’s mana and wealth. There was some difference in carving style between regions and different tribes.

Q. What wood is best for carving NZ?

NZ Heart Kauri

Q. What is the most expensive wood in NZ?

swamp kauri

Q. What is the toughest wood in the world?

1. Australian Buloke – 5,060 IBF. An ironwood tree that is native to Australia, this wood comes from a species of tree occurring across most of Eastern and Southern Australia. Known as the hardest wood in the world, this particular type has a Janka hardness of 5,060 lbf.

Q. What is the heaviest and hardest wood in the world?

Generally acknowledged as the hardest wood, lignum vitae (Guaiacum sanctum and Guaiacum officinale) measures in at 4,500 pounds-force (lbf) on the Janka scale. That’s more than twice as hard as Osage orange (one of the hardest domestic woods) at 2,040 lbf and more than three times harder than red oak at 1,290 lbf.

Q. Does epoxy keep wood from warping?

Some finishes slow moisture exchange better than others, and all finishes do this better the thicker they are. For example, coating wood on all sides with 1/8″ thick epoxy resin comes pretty close to completely stopping any moisture exchange. This warping will occur even if the wood is finished on all sides.

Q. How do you protect wood from warping?

Store your lumber in a clean, cool, shaded and dry location. If you’re storing wood in an area with high relative humidity—80 percent or more—be sure it’s wrapped in material that is impermeable to vapor. This prevents the wood from absorbing significant amounts of moisture from the surrounding air.

Q. How do I keep my 6×6 post from warping?

What I did was run a water hose to the top of the post, wrapped the post about 3″ below the hose with a towel, let the water trickle down all four sides for a couple of days. I then just yanked the post back into position, and screwed a length of 2X6 on either side to “help it hold that position”.

Q. How do you keep pressure treated wood from cracking?

Before driving in a nail or screw, drill a pilot hole to prevent splitting the wood. This is especially important when fastening near the end of a board. Over time, most treated lumber will shrink slightly across its width as it dries out.

Q. What is the fastest way to dry pressure treated wood?

When you want to dry pressure treated wood without it warping, you have two easy options to choose from;

- You can dry out the wood using a home-made wood kiln.

- Or you can stack the wood in a dry place and let it dry out naturally over 2-3 days.

Q. Do you need to let pressure treated wood dry?

The first tip for working with pressure-treated lumber is to let it dry before using it. Other woods such as redwood and cedar are dry when you buy them. But lumber that has been treated has been injected with massive amounts of chemicals and water. When the wood is dry, it may be too hard to nail.

Q. What happens if you paint pressure treated wood too soon?

But, the catch is that you should not paint treated wood too soon after it has been purchased. If you paint treated wood while it is still wet, your coat of primer or paint will most likely be rejected by the water-borne chemicals slowly bleeding their way out of the lumber.

Q. Is it better to stain or paint pressure treated wood?

Because of the pressure-treating process, exterior paint is less likely to adhere to pressure treated wood and more likely to peel. Some experts advise staining or sealing over painting, but paint can be successfully applied by following extra precautions.

Q. Why does pressure treated wood feel wet?

All PT lumber comes wet. They put it under pressure and force chemicals into it. Then they palletize it tightly so it won’t warp in transit and ship it.

Q. Is it OK to build with wet pressure treated wood?

Wet pressure treated wood is all over the place today as treatment remains the primary step of wood protection. So, it’s a big YES, you can build with wet treated wood. The only drawback about this type of wood is that they contain so much moisture components.

Q. Can treated lumber get wet?

While the chemicals in pressure treated lumber prevent rot and ward off insects, they don’t prevent moisture from seeping into the wood. On a deck that’s going to be directly exposed to rain, water can seep into the boards and cause them to swell. As they dry in the sun, they’ll shrink.

Q. How long does it take for pressure treated wood to rot?

Pressure treated lumber exposed to freeze-thaw and wet-dry cycles without care or maintenance will last about 9-years. With proper maintenance and treatment, the same deck will last 40 plus years. Many manufacturers warranty their treated wood for 30 years against rot and insects.

Q. Will wooden posts rot in concrete?

Simply setting the posts in concrete does create a condition that will accelerate rot in the bottom of the posts. With pressure-treated posts, the rot will be slow. The concrete at the top should be sloped away from the post to grade level to avoid water pooling around the base.

Q. Will pressure treated wood rot if buried?

Pressure-treated wood in contact with the ground needs the most protection, and will rot in just a few years if you use the wrong grade. If your wood will touch the ground or be buried, you should get the highest grade you can, up to .

Q. Which lasts longer redwood or pressure treated?

Pressure Treated Pine wins only in the category of below ground use. It lasts longer and is stronger than either redwood or cedar. The two natural woods have a lot of Tannin in them, which is a chemical that prevents rot and insect damage, redwood has more tha cedar so it has a slight advantage.

Q. Can you get pressure treated redwood?

Installation- With some quality woodscrews, a circular saw and a few strong backs, a pressure treated deck can be completed in hours. Redwood often needs to be predrilled, sanded and finished to bring a deck to completion.

Q. Is Redwood ever pressure treated?

Redwood specifically designed for structure use is still a natural wood, but pressure-treated wood contains harmful elements, such as arsenic, copper and chromium. Care must be taken when installing this type of wood by using face masks and gloves to reduce contact with these chemicals.

Q. What are the disadvantages of Redwood?

The disadvantages to redwood are its softness which makes it prone to denting. It is also fairly expensive, especially for premium vertical grain or “All Heart” redwood. In addition, high-quality, stainless steel fasteners must be used with redwood. Otherwise you could stain the wood by using cheaper fasteners.