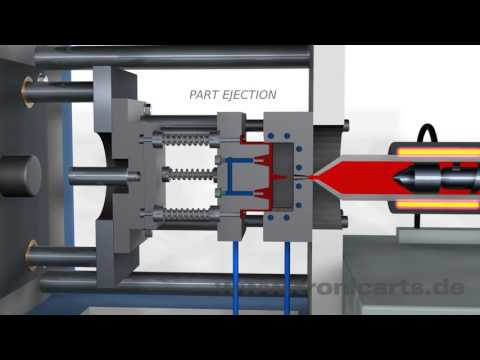

The injection molding machine is consists of four basic parts: the injection unit, the clamping and ejecting unit, electric and hydraulic control unit. The purpose of injection unit is to melt the plastic and conveys or forces the material into the mold.

Q. What is the step by step injection molding process?

These stages are the clamping, injection, cooling and ejection stages.

Table of Contents

- Q. What is the step by step injection molding process?

- Q. What is the process of injection?

- Q. What is shot capacity in injection molding?

- Q. What is the shot capacity?

- Q. How do you calculate barrel capacity?

- Q. How many Litres is a barrel?

- Q. How many inches are in a barrel?

- Q. How do you calculate the weight of mold?

- Q. What is the formula for calculating material weight?

- Q. What material is used as a standard for determining the capacity of an injection cylinder?

- Q. What are the types of injection mold?

- Q. How much does it cost to make an injection mold?

- Q. Is number 7 plastic safe?

- Q. What does a 7 in a triangle mean?

- Q. Which plastic numbers are safe for food?

- Q. What are the safest plastic numbers?

- Q. What is a #6 plastic?

- Q. What are the good plastic numbers?

- Q. Does milk spoil faster in plastic containers?

- Clamping. Before the mould is injected with material, both halves of the mould have to be closed.

- Injection. Plastic pellets are fed by means of a hopper into the injection moulding machine.

- Cooling.

- Ejection.

Q. What is the process of injection?

Injection moulding is a technique used in the manufacturing of plastic products. Injection moulding is a common manufacturing process used to create plastic products and materials. It involves inserting melted plastic into a mould cavity which has been designed into the required shape.

Q. What is shot capacity in injection molding?

The maximum weight of material that can be delivered to an injection mould by one stroke of the ram.

Q. What is the shot capacity?

[′shät kə‚pas· əd·ē] (engineering) The maximum weight of molten resin that an accumulator can push out with one forward stroke of the ram during plastics forming operations.

Q. How do you calculate barrel capacity?

The capacity of a barrel is often measured in gallons. To find how many gallons are in the barrel, simply convert the total volume to gallons. Gallons can be found using the cubic feet to gallons formula: gallons = ft3 × 7.480507.

Q. How many Litres is a barrel?

litres

Q. How many inches are in a barrel?

Cubic Inches to Barrel Conversion Table

| Cubic Inches | Barrel |

|---|---|

| 1 in³ | 0.000103 bbl |

| 10000 in³ | 1.03 bbl |

| 20000 in³ | 2.06 bbl |

| 30000 in³ | 3.09 bbl |

Q. How do you calculate the weight of mold?

For those of you who do not have scales here is an easy way to find mold weight. Measure overall dimensions of the mold. Refer to above image of mold for length, width & height. Measure overall dimensions of the mold.

Q. What is the formula for calculating material weight?

So, to calculate the weight of a strip mill stainless steel plate 304L that is 48″ wide, 96″ long, and 3/16″ or 0.1875″ thick, you’d calculate: Width * Length * Thickness * Density = Weight.

Q. What material is used as a standard for determining the capacity of an injection cylinder?

General Purpose Polystyrene

Q. What are the types of injection mold?

Plastic Injection Mould Types

- Low / High Cavitation. Single cavity molds are designed to produce one part per cycle.

- Family Mold.

- Unscrewing Molds.

- Hot Runner Molds.

- Cold Runner Molds.

- Insulated Runner Molds.

- Two / Three Plate.

Q. How much does it cost to make an injection mold?

A small, single cavity plastic injection mold usually costs between $1,000 and $5,000. Very large or complex molds may cost as much as $80,000 or more. On average, a typical mold costs $12,000.

Q. Is number 7 plastic safe?

#7 plastics are not for reuse, unless they have the PLA compostable coding. When possible it is best to avoid #7 plastics, especially for children’s food. Plastics with the recycling labels #1, #2 and #4 on the bottom are safer choices and do not contain BPA.

Q. What does a 7 in a triangle mean?

Miscellaneous Plastics Any plastic that does not fall under one of those six types has a 7 inside the triangle. These plastics include nylon and polycarbonate and are found in certain food containers, signs and displays, computers and electronic devices, DVDs, sunglasses, and bulletproof materials.

Q. Which plastic numbers are safe for food?

As a general rule, the numbers that are safe for use with food are 1, 2, 4, and 5.

- The best type of plastic for use in long-term food storage is high-density polyethylene (HDPE), which is indicated by the “2” symbol.

- Other types of plastic acceptable for food storage include PETE, LDPE, and polypropylene (PP).

Q. What are the safest plastic numbers?

Remember, number 2, 4 and 5 are safer plastics. Number 1 is also safe, but should not be reused. Numbers 6 and 7 should not be used if you can avoid it. When a plastic says that it is microwavable, remember that it just means it won’t melt in your microwave.

Q. What is a #6 plastic?

Better known as polystyrene or Styrofoam, No. 6 plastics are found in disposable plates and cups, meat trays, egg cartons, carry-out containers, aspirin bottles and compact disc cases. Number 6 plastics have also become notorious for being one of the most difficult plastics to recycle. …

Q. What are the good plastic numbers?

To make a long story short: plastic recycling numbers 2, 4 and 5 are the safest. Whereas plastic numbers 1, 3, 6 and 7 must be avoided. But it does not indicate that you can fearlessly use safer plastic. All plastic products can leach toxic chemicals when heated or damaged.

Q. Does milk spoil faster in plastic containers?

Plastic is lighter, so it takes less energy to ship. And it’s recyclable plastic—though only about one-third of plastic milk containers are actually recycled. It also leads to a faster breakdown of substances that cause milk to spoil, creating off-flavors and that telltale sour smell.