The efficiency of the pulley can increase by reducing the friction in the bearings of pulleys using lubricants. The pulleys in the lower block should be as light as possible because the efficiency is reduced due to the weight of the lower blocks of the pulley.

Q. What happens when you add more pulleys?

When a person uses two or more pulleys in a system, then the system also multiplies the force applied besides changing its direction. With one fixed and one movable pulley in a system, it essentially doubles the weight of the load you could lift without help from another person based upon the weight you can lift.

Table of Contents

- Q. What happens when you add more pulleys?

- Q. How does the number of pulleys affect the efficiency?

- Q. Do pulleys reduce distance?

- Q. What is 1 disadvantage of a pulley?

- Q. What are the 3 types of pulleys?

- Q. What is the formula of effort?

- Q. How do pulleys affect weight?

- Q. How much force is needed to lift the weight pulley?

- Q. What kind of pulley is a block and tackle?

- Q. What is the difference between a pulley and a block and tackle?

- Q. Where is block and tackle pulley used?

- Q. Why is it called a block and tackle?

Q. How does the number of pulleys affect the efficiency?

The more pulleys that are turning, the more friction there is, and the less efficient the system will be.

Q. Do pulleys reduce distance?

Pulleys are usually Force Multipliers – using a simple machine such as a pulley can effectively multiply the force your body produces. However, the rope must be pulled much further because the pulley reduces the distance the object moves.

Q. What is 1 disadvantage of a pulley?

The pulley works on friction. It may slip, then energy loss as heat. To lift an object using combined pulley system, the actual distance traveled by the load increases (increase lifting distance).

Q. What are the 3 types of pulleys?

Among the pulley simple machines, there are three different types of pulleys:

- Fixed pulleys are a very common pulley. These pulleys are secured to a single spot.

- Movable Pulleys are yet another type of pulley.

- Compound Pulley Systems are a combination of both movable and fixed pulleys.

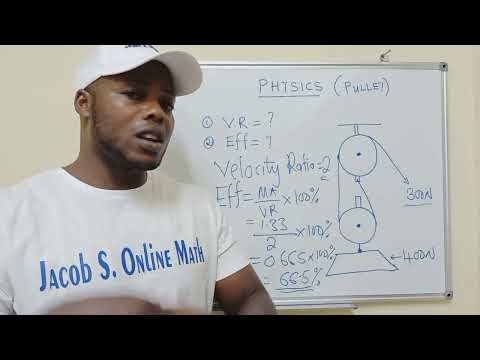

Q. What is the formula of effort?

Follow Us: The formula to calculate force is: force = mass x acceleration, or F = m x a, where force and acceleration have both magnitude and direction.

Q. How do pulleys affect weight?

Pulley FAQ A one-wheel pulley allows you to change the direction of the force you have to apply to lift the load by pulling down to lift a load upwards. Similarly, a two-wheel pulley splits the weight equally so that each holds only half the weight, allowing you to lift the same weight with half of the force.

Q. How much force is needed to lift the weight pulley?

One wheel. If you have a single wheel and a rope, a pulley helps you reverse the direction of your lifting force. So, as in the picture below, you pull the rope down to lift the weight up. If you want to lift something that weighs 100kg, you have to pull down with a force equivalent to 100kg, which is 1000N (newtons).

Q. What kind of pulley is a block and tackle?

A block and tackle or only tackle is a system of two or more pulleys with a rope or cable threaded between them, usually used to lift heavy loads. The pulleys are assembled to form blocks and then blocks are paired so that one is fixed and one moves with the load.

Q. What is the difference between a pulley and a block and tackle?

On its own, a pulley can only change the direction of a force applied to an object. A system of pulleys working together can form a block and tackle, which multiplies force in addition to changing the force’s direction, meaning less force is required to move an object.

Q. Where is block and tackle pulley used?

Block and tackle, combination of a flexible rope, or cable, and pulleys commonly used to augment pulling force; it can be used to lift heavy weights or to exert large forces in any direction.

Q. Why is it called a block and tackle?

Invented by Archimedes around 250 BC, a Block is a set of pulleys on an axle in a housing. When rope is run through a block or a series of blocks, the whole assembly is called a Tackle.